The capsule Filling line is made up of a number of devices that are in charge of creating the capsules needed for pharmaceutical applications. There are various machinery within, including a capsule filling machine, a capsule transporting system, a capsule inspection and polishing machine, a capsule ejector for empty capsules, a capsule sorter for damaged capsules, a capsule counting and filling machine, and a capsule printer. The production of the capsules with the appropriate therapeutic content is carried out by the aforementioned machinery. Nowadays, capsules are widely used because most individuals prefer to take their medications as pills. Therefore, it is crucial to produce the capsules or pills with the highest level of accuracy, free from any errors or adulterants.

Equipments in the Capsule Line

-

Capsule Conveying Machine

Capsule Conveying Machine

From one station to another, capsules are moved via a capsule conveying system. Due to their fragility and brittleness, the tablets or capsules are prone to damage. A capsule conveying system provided by Adinath International is capable of moving up to 48000 capsules per hour. The machine needs to be strong and have a high-quality final surface.

-

Capsule Filling Machine:

Capsule Filling Machine:

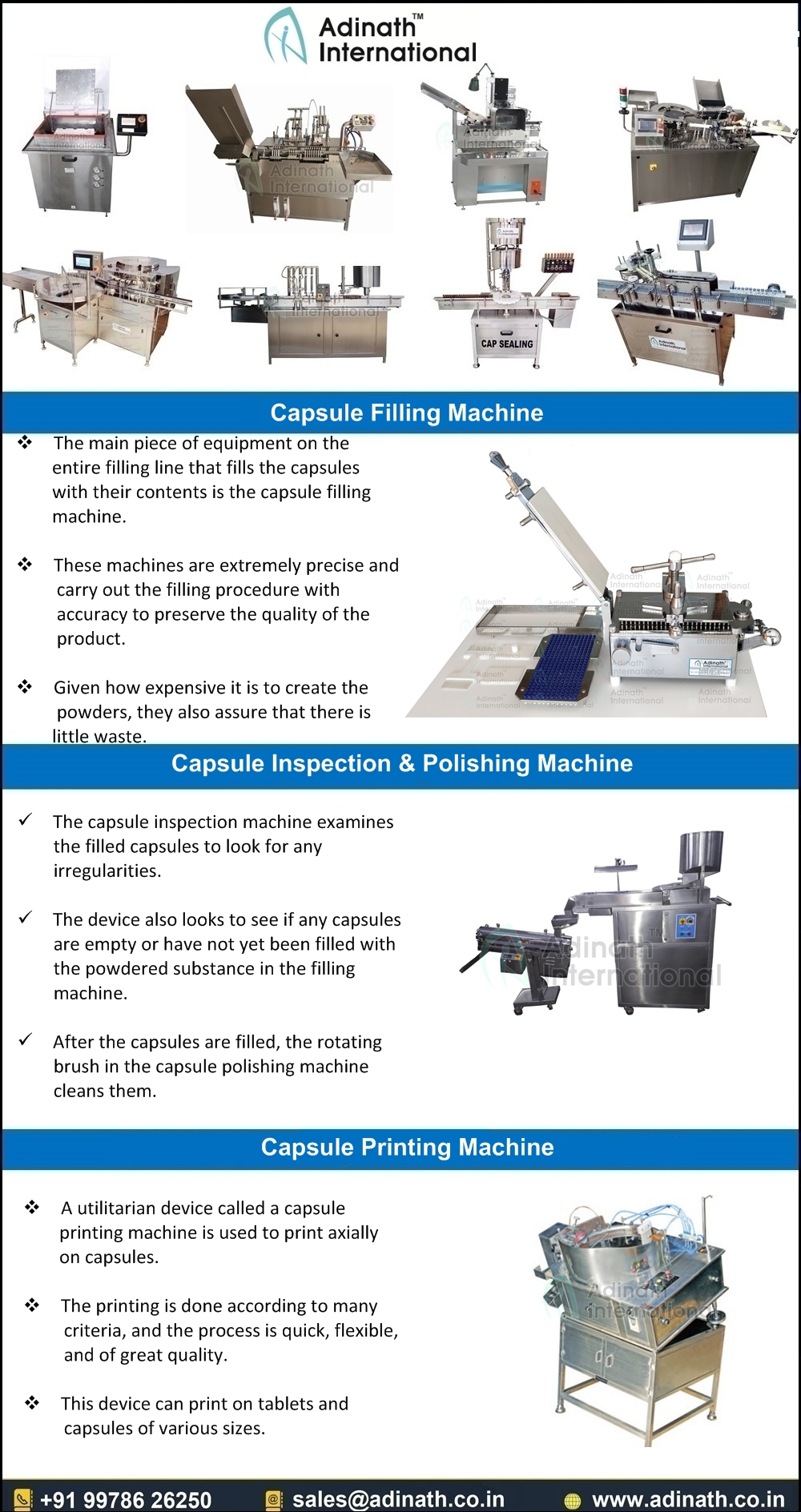

The main piece of equipment on the entire filling line that fills the capsules with their contents is the capsule filling machine. On the basis of how they operate, the filling machines can be further classified into three types: high-speed capsule filling machines, semi-automatic filling machines, and manual filling machines. These machines are extremely precise and carry out the filling procedure with accuracy to preserve the quality of the product. Given how expensive it is to create the powders, they also assure that there is little waste.

-

Capsule Inspection & Polishing Machine:

Capsule Inspection & Polishing Machine:

The capsule inspection machine examines the filled capsules to look for any irregularities. To guarantee a good quality lot, it removes the batch’s subpar capsules. The device also looks to see if any capsules are empty or have not yet been filled with the powdered substance in the filling machine.

After the capsules are filled, the rotating brush in the capsule polishing machine cleans them. Capsules are fed into the polishing chamber, which has a spiral brush that rotates to remove powder particles attached to the outside of the capsules.

-

Empty Capsule Ejector:

Empty Capsule Ejector:

Empty capsules are separated from the batch using an empty capsule ejector. It operates on the force of airflow. The filled capsules go down in a straight line after strong wind is applied, but the empty capsules are expelled outside.

-

Damage Capsule Sorter:

Damage Capsule Sorter:

Damage capsule sorters are devices created especially to separate out capsules that are loose or otherwise defective. These pills compromise the quality of the entire batch. The damage capsule sorter is a flexible piece of machinery that can be connected to any other device.

-

Capsule Counting and Filling Machine:

Capsule Counting and Filling Machine:

On a modest scale, capsules are counted and filled using a machine. Pharmaceutical, nutraceutical, cosmetic, herbal, and ayurvedic industries are just a few of the ones where the application is used. The equipment has a filler, hopper, and vacuum system that allow stocks to be transported to the container without being covered in dust.

-

Capsule Printing Machine:

Capsule Printing Machine:

A utilitarian device called a capsule printing machine is used to print axially on capsules. The printing is done according to many criteria, and the process is quick, flexible, and of great quality. This device can print on tablets and capsules of various sizes.

The Bottom Line:

In the market, Adinath International is well renowned for offering top-notch equipment to the pharmaceutical sector. The production facilities boast of all the cutting-edge machinery necessary to create machines with excellent productivity and easy usability.

Our company’s capsule filling line machine has numerous line components that make the entire process accurate and error-free.