Particularly in Asia, the USA, and Europe, servo-based ampoule filling machine’s are employed in the chemical and pharmaceutical sectors.

Ampoule filling equipment is thought to be in high demand and of the highest calibre in Europe. Liquid, powder, and capsule forms of pharmaceutical medicines are produced. For example, producers employ machines like capsule filling machines, ampoule filling machines, and liquid bottle filling machines to package pharmaceutical products. All of these products require sophisticated machinery to create and package them.

Here is a fast guide to assist you navigate through all parts of the ampoule filling machine if you are a pharmaceutical company in the USA or Europe seeking for a dependable Servo-based ampoule filling machine that aids in the efficient processing of pharmaceutical products, notably liquid:

Advantages of Servo based Ampoule Filling Machines :

-

Increased Production Capacity :

Increased Production Capacity :

Up to 200 ampoules per minute can be produced with servo-based ampoule filling Machine. This machine ensures a high output to satisfy your ampoule production needs. The machine not only has a great output capacity, but it is also quicker and more effective. It enables a quicker switchover, which saves time.

-

Ensure the Best hygiene Standards :

Ensure the Best hygiene Standards :

Ampoules are glass containers that hold the contents, so they are kept germ- and dust-free. Ampoule filling machines can hold the precise amount of substance that ensures purity and minimises waste, regardless of whether the medicine is solid or liquid. The contents can even be kept for a very long period.

-

Comes with a Pre-Warming System :

Comes with a Pre-Warming System :

You no longer have to be concerned about the ampoule filling machine overheating. The technology can automatically heat the bed thanks to a pre-warming bed, which lengthens the machine’s lifespan and increases its toughness.

-

Easy Maintenance :

Easy Maintenance :

The co-eccentric nozzles on servo-based ampoule filling machines provide speedy and accurate filling in addition to being simple to use. All you need to do is load the ampoules with the products you choose to fill them.

You no longer have to be concerned about extensive maintenance. The servo-based ampoule filling machine is also very simple to maintain. In the event of a mistake, the machine will automatically deflect, and you can keep an eye on the entire ampoule filling procedure and adjust the parameters as necessary.

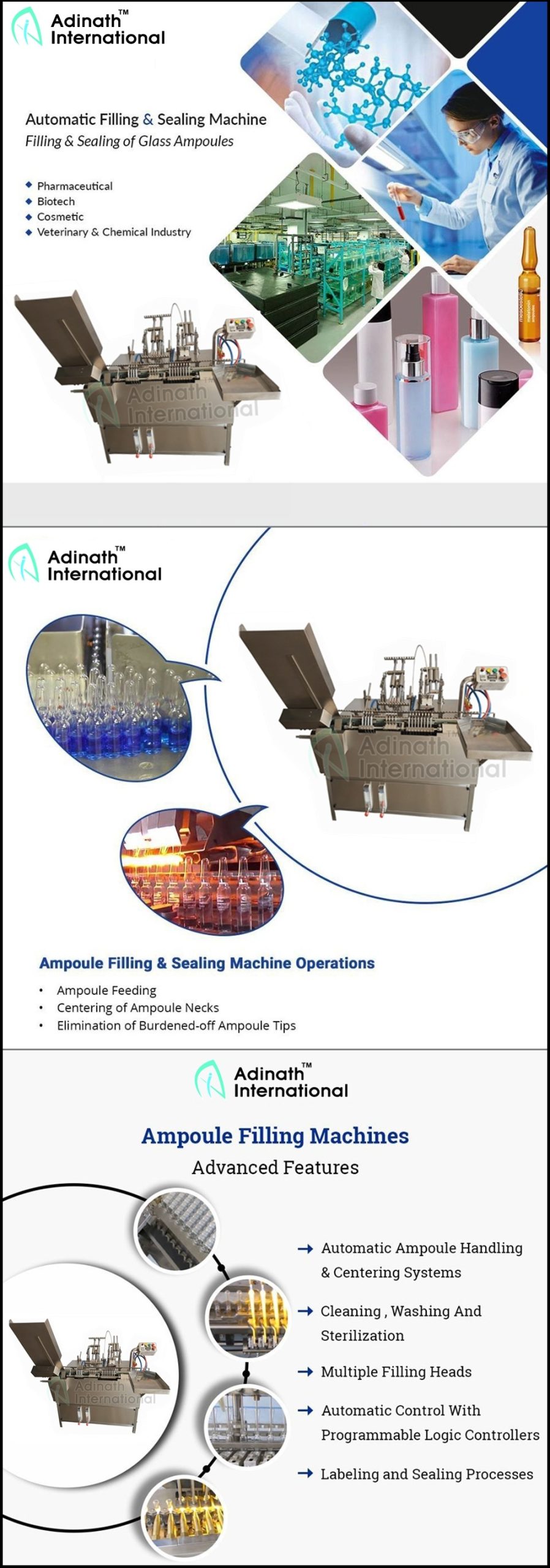

Application for the Servo Based Ampoule Filling Machine :

The machine can be employed in a variety of sectors due to its flexibility. Let’s look at them now:

-

Pharmaceutical Industry :

Pharmaceutical Industry :

Ampoules shield the contents from air and other pollutants, as was already indicated. For processing medications in the industry, European and American nations have employed these equipment for decades with great success.

-

Food Industry :

Food Industry :

Do you work in the food business? The ampoule filling machine’s automatic liquid filling can then be of great assistance to you. The adoption of this machine has improved the instant beverage sector.

-

Cosmetic Industry :

Cosmetic Industry :

Even the US and European cosmetic industries heavily rely on ampoule filling equipment for the production and processing of natural oils and body lotions. With the aid of this equipment, mascara and other beauty products can also be produced.

-

Chemical Industry :

Chemical Industry :

Do you require assistance handling many chemical liquids? There is no need to search farther; a servo-based ampoule filling machine can correctly process and package all the chemicals.

Conclusion

Knowing the uses for this equipment, you may rest assured that they are practical, dependable, protective, and adaptable to your requirements.

Ampoule filling machines are the solution if you want to fill vials quickly and creatively. You can decide which one best meets your requirements.