Description

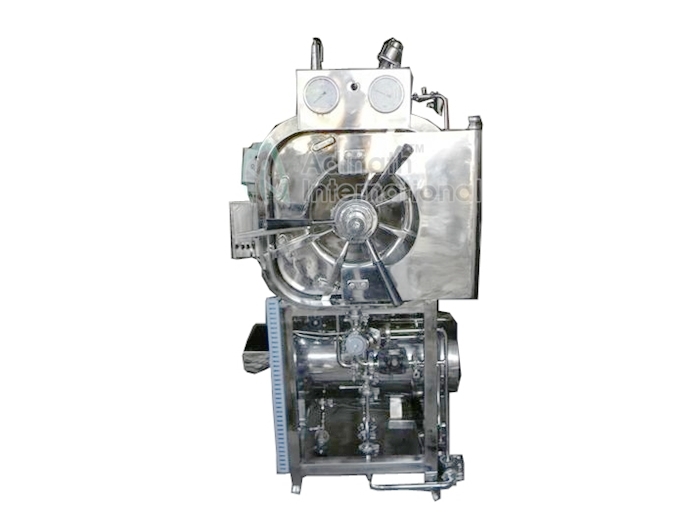

Autoclave sterilization or steam sterilization is uses to terminate bacteria and spores using heat generated due to pressurized steam. Adinath International is a leading steam sterilizer manufacturer in India with a significant track record. Our steam sterilizers are pretty simple in construction and use. They use saturated steam between 121°C and 132°C. Simply put it is a wet heat process and the low water content of oils results in effective sterilization. There are a plethora of advantages of using steam sterilizers. They are environment friendly, easy to use, cost-effective and highly efficient.

Being one of the best steam sterilizer manufacturer and supplier in India, we offer the following steam sterilizers-

- Sliding door horizontal steam sterilizer

- Horizontal rectangular sterilizer

- Horizontal cylindrical sterilizer

- Double walled vertical autoclave

- Triple walled vertical autoclave

As a pioneering steam sterilizer provider in India, we are capable of offering customized vertical steam sterilizers in line with your unique needs whilst complying with all national and international standards such as NABH standards. We also offer IQ/OQ/DQ documentation as per particular requirements.

Features of Steam Sterilizer

- Digital temperature controller.

- Digital temperature indicator.

- Interior made with stainless steel.

- Gasket made of silicon rubber.

- ISI approved Immersion heating elements and flange.

- Temperature range up to 121°C.

- Automatic pressure control system.

- Steam pressure gauges with high reliability.

- Water level indicator.

- Double or triple wall construction

- Pedal for opening the lid

- Water level indicator

- Water inlet and outlet valves

Working Principle of Steam Sterilizer

The principle of steam sterilization is pivoted on exposing objects to steam for a pre-specified amount of time and temperature. This equipment is uses in medical facilities to sterilize the surface of wrapped goods or hollow objects. There are three key parameters in steam sterilization: temperature, steam under pressure and time.

Dry and saturated steam is supplied under a particular pressure into the autoclave. Microorganisms are eliminated due to the heat from condensation. This happens due to an irreversible damage caused to the cells of microorganisms because of coagulation.

Technical Specification of Steam Sterilizer

| Construction | Standard Model | Double Walled Model | Triple Walled Model |

| MOC Exterior | MS Painted | SS 304 (mirror finish) | SS 304 mirror finish) |

| No. of walls | Double | Double | Triple |

| Lid | Polished MS | SS 304 | SS 304 |

| Interior | SS 304 with silicon gasket | ||

| Working Pressure | 15 to 20 PSI | ||

| Working Temperature | 121°C to 125°C | ||

| Controller | 15 PSI & 121°C | ||

| Pressure display | Analog dial gauge | ||

| Timer | Mechanical timer | ||

| Hydraulic tested | Hydraulically Tested up to 40 psi | ||

| Basket | Stainless steel basket | Stainless steel basket | Not Required |

| Power supply | 220 Volts, Single Phase, 50Hz | ||

| Standard Fittings |

|

||

| Optional Accessories |

|

||

* Power voltage can be adjusted as per customer’s domestic power voltage requirements.

* Rights of technical improvements & modification reserved.

* Illustrations & dimensions are shown for information purpose only.