Description

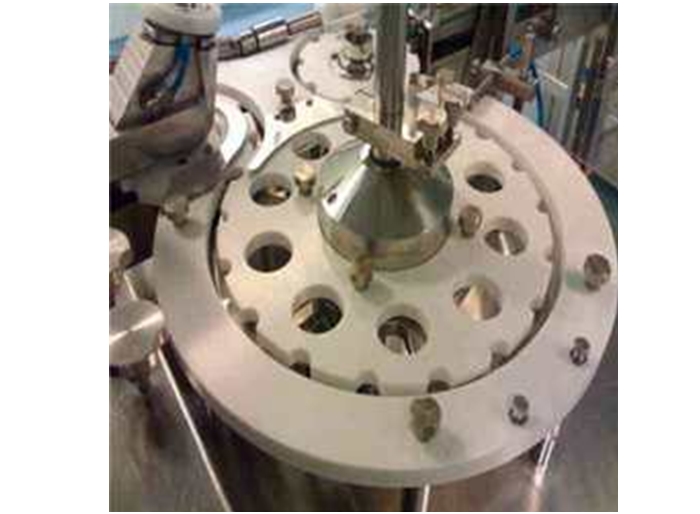

Automatic Prefilled Syringe Filling Machine is suitable for the filling prefilled syringe uses in pharma applications. Machine is compact and provides higher production output. Machine is suitable for application in pharmaceuticals, biotech and Biopharmaceutical industry.

Salient Features of Pre Filled Syringe Filling Stoppering Machine

Process Operation of Pre Filled Syringe Filling Stoppering Machine

Syringes loaded on Stainless Steel in-feed hopper. Prefilled syringe tray can directly loaded on to the machine. Syringes move from infeed station to the filling station filling is done by electronic pump. After desired volume filling syringe transfer on stoppering station stoppering is done on well designed manner. Duly filled & stoppered syringes delivered on outfeed collection tray without hand touch.

Technical Specification of Pre Filled Syringe Filling Stoppering Machine

| Model | PFSM – 40 |

| No. of Filling Syringes | Two |

| Tray Holes | 10 rows x 10 nos. = 100 holes |

| Filling Volume | 0.5ml to 5ml |

| Production Output | Up to 1440 syringes/hour |

| Filling Accuracy | ± 1% |

| Utility | Purified Air and Nitrogen |

| Electrical Characteristics | 230 Volts, Single Phase, 50 Hertz, 4 Wire System |

| Contact Parts | Made from Stainless Steel 316L |

| Non-Contact Parts | Made from Stainless Steel 304 |

| Overall Dimension | 1300mm (L) x 600mm (W) x 1200mm (H) approx. |

| Net Weight | 250 kgs. approx. |

| Gross Weight | 375 kgs. approx. |

| Change Parts – Filling Unit | Filling Syringes for 5ml – 10ml (If required) |

| Change Parts – Stoppering Unit |

|

* Power voltage can be adjusted as per customer’s domestic power voltage requirements.

* Rights of technical improvements & modification reserved.

* Illustrations & dimensions are shown for information purpose only.