The tablet press machines is a vital component of the pharmaceutical industry and sector. The tablet press machine is also termed a tablet press, tablet compression, tableting machine and pharmaceutical tablet press machine.

The machine is primarily used for making a wide variety of tablets in a uniform shape from different types of materials like powder formed and many more. During the tablet-forming process, the granulated powder is filled in between the cavity formed by the punches and dies. The punches are pressed together with a lot of force to prepare the tablet.

The pharmaceutical industry has been dominated by these tablet press machines owing to the rising demand for tablets due the consumers’ habits and needs. This article will delve deep into the intricate details of different types of tablet press machines and narrate an in-depth understanding of the designs and functions of the machines.

The types of tablet machines in the pharmaceutical sector are as follows:

- Single Punch Tablet Compression Machine

A single punch tablet compression machine helps pharma companies to produce drugs into round tablets and in relatively smaller batches. These machines manufacture chewable tablets, effervescent tablets, and other powdered tablets. This machine provides a high utilization ratio with required adjustments and settings.

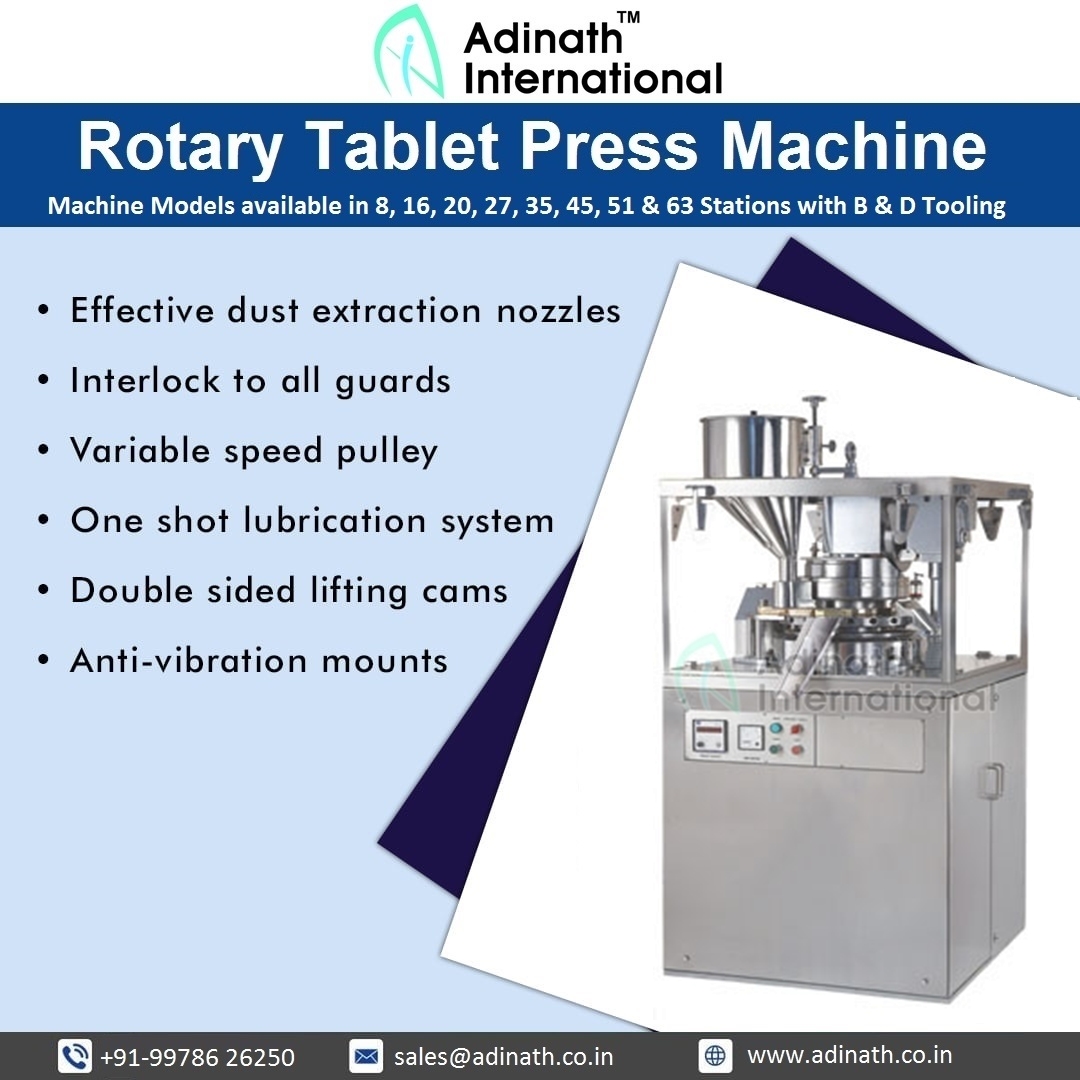

- Rotary Tablet Compression Machine

Preferred for high-volume manufacturing, the rotary tablet compression machine

is used by various businesses, such as the pharmaceutical, nutraceutical, and cosmetic industries. The machine also uses several tooling stations to compress powder combinations into tablets.

The machine has a hopper, feeder, slider, and other adjustable options, as per the model. The setup is considered to be more effective than the single punch tablet compression machine, as the former enables one to control the manufacturing process, thereby reducing the amount of powder formulation waste.

Pharmaceutical Tablet Press Machines

Pharmaceutical tablet press machines are able to produce several pharmaceutical, nutraceutical, cosmetic, or industrial tablets. These machines adopt stationary or rotary punchers to compress the raw powder or granule into a tablet. These machines are noted to be a faster and an efficient way of producing pharmaceutical tablets.

The main feature of the pharmaceutical tablet press machine is the overload protection unit that is equipped in the machine to avoid damage to the punches and apparatus. The machine automatically stops working owing to the possibility of overload.

One may note that such pharmaceutical tablet press machines initially incur huge costs and further require proper calibration and maintenance. Additionally, safety rules should be adopted while working on pharmaceutical compounds.

Key characteristics of the pharmaceutical tablet press machines:

- Apart from focusing on product quality and adherence to specifications, the tablet press machines ensure the production of tablets with consistent shape and size.

- By focusing on high-pressure application, the machine operates by applying high pressure to compress the powder or granules, ensuring efficient tablet formation and uniformity.

- The tablet press machine has been designed for batch production, allowing for efficient manufacturing processes and increased productivity.

- Further, the machines are being employed in the batch production of salt drugs for pharmaceutical, food, and chemical products.

- The tablet press machine is also being used for manufacturing salt tablets present in pool water treatment to purify water.

- The machine utilizes a rotary press mechanism where punches are operated to compress granules and powders by applying high pressure. This mechanism allows the efficient blending of substances and precise tablet formation.

Chemical Tablet Press Machines

Chemical tablet press machines are high-speed rotary tablet presses that are aimed at the chemical and related industries. These machines are capable of generating 100 kN pre-pressing pressure and have the ability to produce tablets up to varied in thickness.

Designed to meet the demands of large manufacturers, the chemical tablet press machine features high automation with a high utilization ratio that possesses the ability to bear heavy loads.

Salt Tablet Press Machines

The rotary tablet machine is the most modern press machine used in tablet salt making and utilized for compressing salt. The tablet salt production has a standardization for working automatization of the machine. The salt tablet press machine structure is strengthened on the basis of the salt tablet production requirement.

Hydraulic pressure is the basic force that works on the salt tablet press machine. This pressure is transmitted and not reduced from a static liquid. Further, the surfaces that touch salt are manufactured from stainless steel. This machine has recorded minimum wastage of time and effort as feeding, compressing, and removing processes are duly automatic.

These machines produce high-quality tablets making them ideal for usage in applications such as water treatment, food processing, and agriculture. These salt tablet press machines are majorly adopted in the pharmaceutical, chemistry, foodstuff, and electronic sectors.

The rotary tablet press machines have multiple tooling stations that rotate to compress granules into a tablet of uniform size, required shape and uniform weight. During the rotary presses, the compressive force on the fill material is applied by both the upper and lower punches, thereby allowing the granules to compress in the middle.

Also known as the multi station machine, the main goal of the rotary tablet press machine is to boost tablet output. The rotary tablet press machines combat the wastage of formulation, thereby saving production costs and generating high volume capacity. The operations are eased as the compression cavity is being controlled automatically.

Mini Tablet Press Machine

The mini tablet press machine has been designed to cater to small batch production requirements. This tablet press machine is a compact table-top machine that has been aptly designed to produce round, oval, and caplet shaped tablets. Termed as the mini tableting machine, the machine is widely employed for the purpose of formulation as well as research and development.

The machine has a compact design with an outside hopper, and the parts can be easily detached for cleaning and autoclaving. As the press machine is small in size and easy to operate, one needs to spend minimum time and effort on the maintenance aspect. Mini tablet press machines are preferably used to avoid wastage when high-value ingredients have been used for tablet formulation.

The single rotary tablet press machine is a highly compatible machine, extensively used in the pharmaceutical and food industries. It is designed for small-batch production. Unlike the double-sided rotary tablet press machine, the powder mixture in the single rotary tablet press is fed into a die where it is compressed by a single rotating punch.

It is important to note that the main pressure and pre-pressure of a single rotary tablet press machine may be altered. The pressure values depend on the size of the compress and the filling depth. It additionally depends on the physical specification of the material that is used for compression.

A beneficial application of a single rotary tablet press machine is that the machine is a single-tooled equipment. The acrylic material construction of this single tool makes the machine lightweight and durable, helping the machine to function seamlessly with the existing load.

The double-sided rotary tablet press machine is utilized to produce tablets with a rapid speed as the mechanism of the machine executes the process by applying high-level precision. The double rotary tablet press machine produces tablets with a rapid speed as the mechanism of the machine executes the process by applying high-level precision.

A double rotary tableting machine creates definite and simple tablets from powdered material. This machine is majorly utilized in the pharmaceutical, herbal medicine producing industry, ceramics, and other associated industries.

The machine processes the tablets by punching and filling the powder and granules in the tablet. In the tablet compressors, the electrically operated counter machine lifts the tablets with the help of a double lifter camp, present in the electrical tablet press.

In contrast to the single rotary tablet press machine, a double rotary tablet press has two rotating punches that compress the powder mixture in two separate dies.

Considered one of the best tools in the pharmaceutical industry, the tablet press machine is named one of the most advantageous investments for any industry or factory.

The tablet press machine is designed and operated as per the functioning principles, some of the aspects are listed as:

- Working principles of the tablet press.

- Different principles can be applied to rotary tablet presses.

- Mini tablet press principles.

Tablet press machines are available in two main designs, mainly:

- Single Station – This design was one of the previous models of the tablet making machines. Also known as the eccentric press, the single-punch pharmaceutical press machine possesses a low production capacity. The design is relatively meant for low production capacity or approximately 60 tablets per minute. This design is adopted in the domain of research and development and also for clinical trials.

- Multiple Station Machines – The machine manufacturers have been successful in developing innovative designs with the latest technologies that have been designed to handle the varied physical and chemical properties of tablets. Other features include a modified feeding system catering to types of powder characteristics, and digitalized tablet counters and stainless steel construction enhancing life of the machine.

Tablet Making Machine

The tablet making machine, also known as the tableting machine is the machine used to make tablets in many sizes as per the requirements. It can transform the product from powder form to tablet form. The tablet making machines are highly adopted in the pharmaceutical sector to produce medicine tablets.

Benefits of using a tablet-making machine

- One can have complete control over the process with the availability of different configuration settings.

- Production capacity can be increased to meet the growing demand for tablets and can be fine-tuned to meet the industry’s production requirements

- The tablet making machine does not allow air, bacteria, or germs to enter into the compartment, thus maintaining the required cleanliness and hygiene standards of the pharmaceutical industry.

Tablet Compression Machine

A tablet compression machine is a mechanical device that is widely used to compress active pharmaceutical ingredients and excipient granules or mixtures into tablets of a uniform and predetermined size, shape, and weight for research, pilot-scale manufacturing, and full production.

A tablet compression machine is also recognized as a tablet press machine, tablet making machine, tablet machine, or tablet punching machine.

Some of the common names of tablet compression machine manufacturers are as follows:

- Bosch

- Korsch

- GEA

- Cadmach

- Fette

- Kilian

- Natoli

Applications of Tablet Compression Machine

- It is mainly used to compress the granules or mixture of active pharmaceutical ingredients and excipients to uniform and predetermined size, shape, and weight of tablets for new tablet development and small batch production.

- It is employed to crush the granules/powder mix into tablets for small-scale production as well as full-scale production.

- It is utilized to compact the blend of powder in the dry granulation method.

- It is used to compress multi-layer tablets such as bi-layer, tri-layer, four-layer, and five-layer tablets.

Steps involved in the maintenance of a tablet compression machine:

- After an operation, turn off the electric supply.

- Dismantle all the common jointed parts and remove powder dust and wasted granules with the help of a vacuum cleaner.

- Dismantle all punches and clean all surfaces of the tablet compression machine with a dry lint-free soft cloth followed by a compressed airflow.

- The surfaces of the tablet press machine and its functional parts should be wiped properly.

- Finally, clean the tablet compression machine parts, and other accessories with potable water and rinse with purified water.

Tablet compression machines are also useful in making tablets form of other cleaning products and for the cosmetic industry.

Final Thoughts

Apart from tablet making, the tablet press machine is also used in the research and development department for any experiments with tablets.

The tablet press machine is a versatile piece of equipment utilized in various industries for tablet production. It provides several characteristics that contribute to its effectiveness and efficiency in producing uniform-shaped and desired-sized tablets. A tablet press machine offers advantages such as consistent tablet quality, higher production efficiency and lower cost of production.

In order to reap the maximum benefits, the company must purchase a tablet press machine from high-quality machine manufacturers.