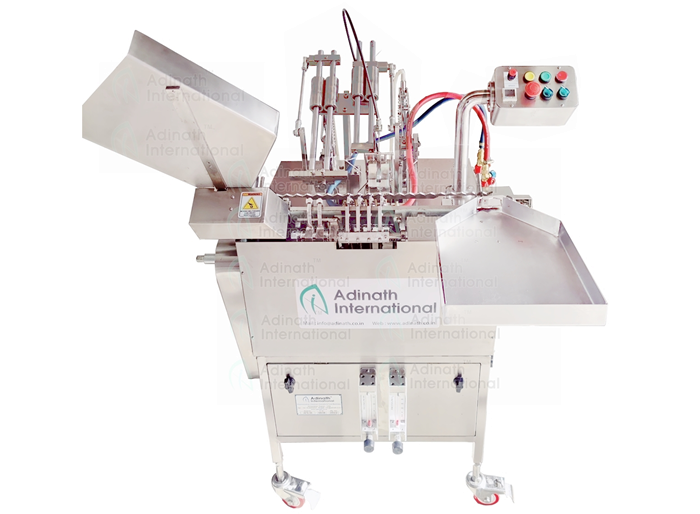

Ampoule Filling Machine for Crushable Ampoules

A specialized piece of machinery used in pharmaceutical manufacture, an automatic crushable ampoule filling machine fills and seals ampoules that are intended to be readily broken or crushed in order to release the contents. These kinds of ampoules are frequently used for administering single-dose liquid drugs, immunizations, or other chemicals in a fast and convenient manner.

Types of Biological Indicator Filler and Crushable Ampoule Sealer

Pharmaceutical crushable ampoule filling machine, Single head crushable ampoule filling machine, Double needle crushable ampoule filling machine, Two head crushable ampoule filling machine, Single needle crushable ampoule filling machine, Four head crushable ampoule filling machine, Eight stroke crushable ampoule filling machine, Six head crushable ampoule filling machine, Six stroke crushable ampoule filling machine, Eight head crushable ampoule filling machine, Four stroke crushable ampoule filling machine, Vertical crushable ampoule filling machine, Double stroke crushable ampoule filling machine, Horizontal crushable ampoule filling machine, Dual stroke crushable ampoule filling machine, Compact crushable ampoule filling machine, Single stroke crushable ampoule filling machine, Small crushable ampoule filling machine, Lab-scale crushable ampoule filling machine, Pilot scale crushable ampoule filling machine, R&D crushable ampoule filling machine, crushable ampoule filler and sealer, Biological indicators sealer, crushable ampoule filling and sealing machine, biological indicator filling and sealing machine.

An Outline of the Main Attributes and Capabilities of an Automatic Crushable Ampoule Filling Machine is Provided Below:

Ampoule Filling:

The apparatus is intended to process a batch of ampoules that can be crushed. To be filled and sealed, empty ampoules are placed into the machine’s holders or chambers.

Stuffing:

The filling procedure precisely transfers the prescribed volume of liquid drug or material into the crushable ampoules. Precision and uniformity are guaranteed by the dosage mechanism.

Closing:

The procedure of sealing happens after filling. Sealing techniques can include heat sealing or flame sealing, depending on whether glass or plastic ampoules are being used. Until the ampoule is crushed for use, the sealing guarantees that the contents are safely contained.

Examining and regulating quality:

Certain machines may have inspection devices to verify that the seals are intact and free of any flaws that could lower the ampoules’ quality.

Control and Automation:

To guarantee reliable and effective processing of the ampoules, these devices are often automated.

Adherence to Regulations:

Crushable Ampoule Filler and Sealers are subject to stringent regulatory requirements, just like any other pharmaceutical manufacturing equipment, in order to guarantee product safety and compliance.

When it comes to guaranteeing the precision and sterility of the contents and preserving the ampoules’ integrity until they are prepared for use, crushable ampule filler and sealers are indispensable. Pharmaceutical production lines frequently use these devices, particularly in environments where single-dose administration is prevalent.