Principle Importance of Ampoule Washing Machine

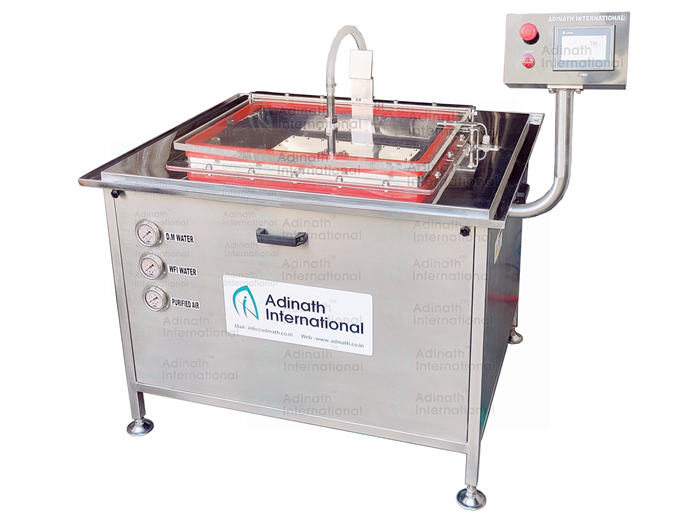

In the pharmaceutical, biotech, and other industries where sterile packing is crucial, ampoule washing machine are vital pieces of equipment. Before they are filled with drugs, vaccines, or other sensitive goods, ampoules—small sealed vials—are meant to be cleaned and sterilized. The following information provides a general overview of ampoule washing machine:

Objective: Cleaning impurities, dust, and microbes off the surface of ampoules is the main function of an ampoule washing machine. By ensuring the ampoules are sterile and clean, this procedure helps to prevent product contamination.

Cleaning Method: To accomplish cleanliness, ampoule washing machine usually use a mix of washing, rinsing, and drying procedures. Pre-washing, main washing, rinsing with purified water, and drying with filtered air are some examples of the precise stages.

Device Types:

Automatic: Fully automated devices that need little assistance from the operator. They work well in large-scale manufacturing.

Semi-Automatic: Ampoules must be manually loaded and unloaded by these machines. They are commonly employed in production on a medium scale.

Condensed: These machines are space-efficient and efficient in their smaller form, making them ideal for smaller facilities.

High Speed: These devices can clean quickly and are appropriate for producing pharmaceuticals on a large scale.

Cleaning Conditions: Ampoule washing machine have adjustable water temperature, pressure, cycle length, and number of washes, among other factors. It is possible to adjust these values to meet certain cleaning needs.

Immaturity: It is essential to guarantee the sterility of ampoules. To keep an environment sanitary, several devices use sterilization techniques including clean-in-place (CIP) and steam-in-place (SIP).

Desiccation: To avoid residual moisture inside ampoules, which can cause contamination or product degradation, effective drying is crucial. Equipment frequently has air drying systems.

Verification: An essential component of ampoule washing is validation of the cleaning procedure. Cleaning validation studies are necessary for pharmaceutical businesses to make sure the equipment regularly reaches the required level of cleanliness.

Compatibility of Materials: Ampoule washing machines are made to handle a wide range of ampoules, including ones with varying sizes and compositions like plastic and glass.

Respect for Regulations: Regulations such as current Good Manufacturing Practices (cGMP) and FDA requirements must be followed by these equipment. They ought to supply the required paperwork and assist with validation procedures.

Guarantee of Quality: To ensure the safety and effectiveness of the product, a strong quality assurance program needs to be in place to oversee and manage the cleaning procedure.

Operator Education: For the equipment to be operated correctly and for the cleaning process to be reliable and efficient, personnel must receive the necessary training.

Remainder: To prolong the machine’s lifespan, minimize downtime, and maintain optimal operating condition, routine maintenance is necessary.

Equipment for washing ampoules is essential in the pharmaceutical and other industries where high standards for product quality and sterility apply. They are made to withstand strict regulatory standards and contribute to the efficacy and safety of medicines and other delicate goods that are contained in ampoules.